Trade Air Australia Ductwork Components

Ductwork components are found in every heating and cooling system, whether residential or commercial. It is responsible for carrying the cooled or heated air into the desired areas. Trade Air Australia provides all your ductwork component design and supply needs including manufacturing custom works for those pesky jobs.

What is ductwork?

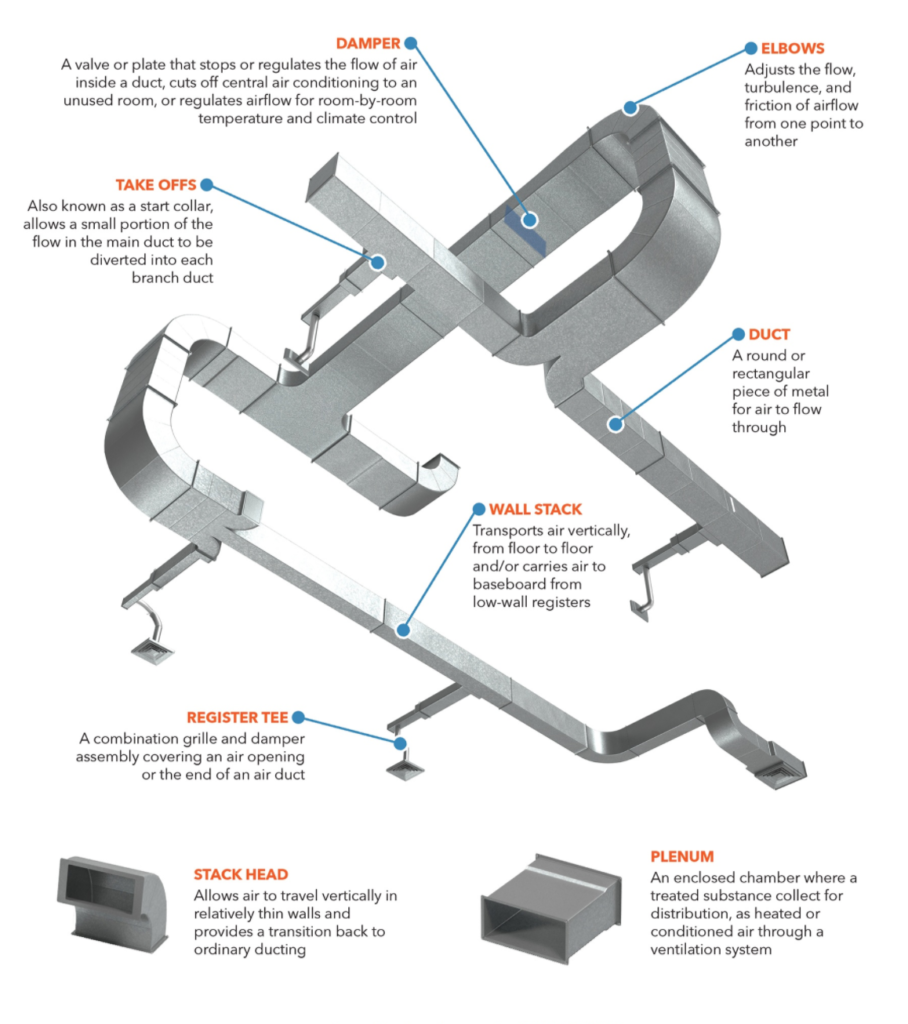

Ductwork is a network of large tubes that extend from your return air box (where the air is drawn into the indoor unit) to the diffusers (where the cooled or heated air enters the area) throughout the commercial or residential building.

The normally out-of-sight tubes are often round (flexible) or rectangular (metal) and are frequently installed inside the ceiling cavity. Ductwork can also be visible for an industrial aesthetic feel if desired.

What does ductwork do?

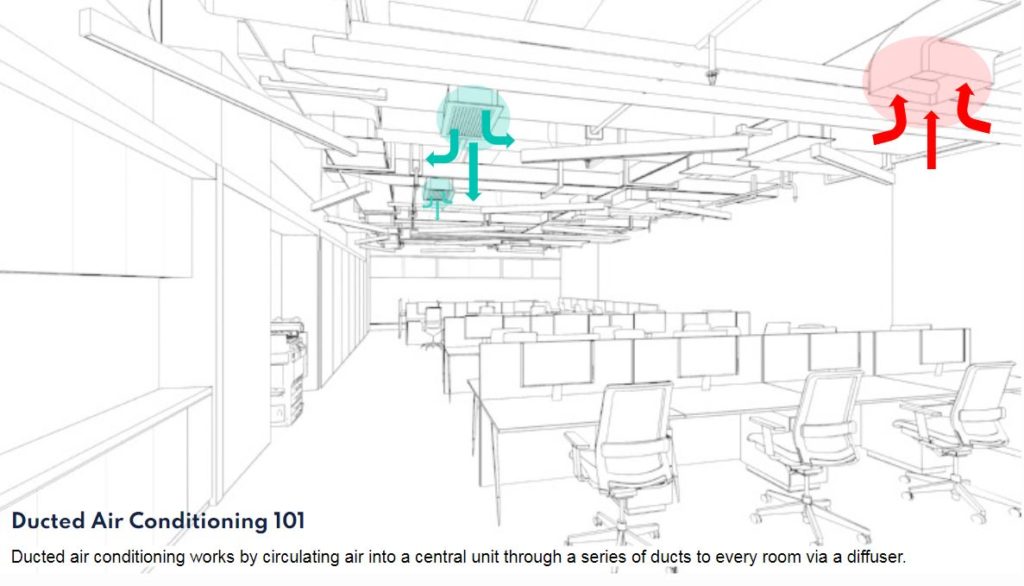

Ductwork is responsible for carrying the heated or cooled air produced by air conditioner into the required indoor areas of the residential or commercial building.

Supply ducts send heated and cooled air from the indoor unit to the indoor area, while return ducts draw expended air back to the return air box to be filtered, reconditioned, and redistributed.

Why is ductwork important?

Ductwork helps regulate the comfort and indoor air quality of your building. Without them, these necessities would be compromised in the form of air leaks, hot and cold spots, drafts, mould growth, unbalanced air pressure, lingering odours, and excessive noise from the indoor unit.

Why is ductwork design critical?

Ductwork requires design, measurements, and careful ductwork installation. The size and shape of the ductwork affect air friction loss. Flexible ductwork has the highest friction loss per linear metre, while rounded galvanized (metal) ductwork has the least.

For the best design, a minimal amount of high-quality smooth fittings are used to reduce the system’s air pressure drop. A direct route ensures minimal air friction loss.

Undersized systems are often too loud, and poorly installed fittings can cause turbulence that increases the noise level. To lessen noise levels, dampers that are located away from registers and diffusers are used.

Any ductwork that runs from warm areas to cold ones can lose efficiency. Uninsulated and leaky ducts result in higher energy bills, occupant discomfort and odours.

What is the difference between Metal and Flexible Ductwork?

What’s a metal duct?

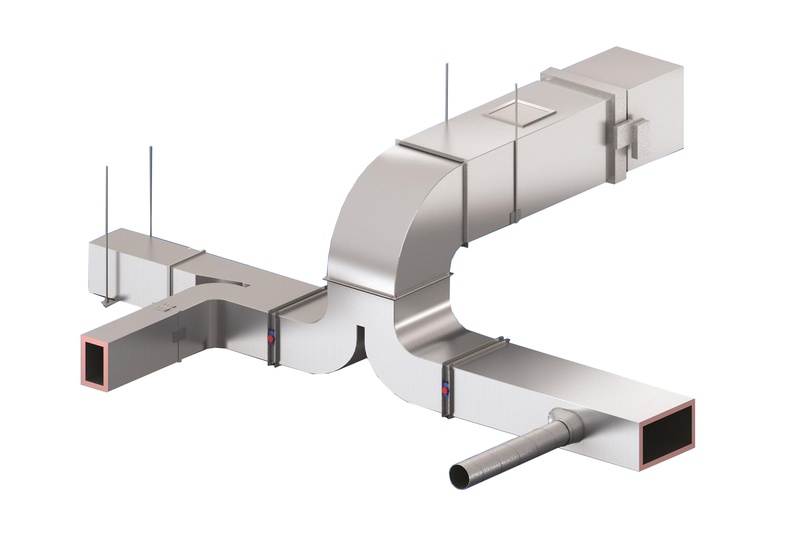

Metal ductwork offer a more permanent solution to a commercial air conditioning system. Galvanized steel and aluminium ductwork last longer when proper maintenance occurs on a regular schedule.

What’s a flexible duct?

The flexible ducting connects the metal ductwork to carry the air to the diffusers.

Insualted flexible duct is used to transfer conditioned air. Non-insulated flex duct is used typically used for ventilation and non-conditioned air.

How do these differ?

Flexibility. Flex ducts are better for existing trunk-and-branch heating and cooling systems.

Installation. In comparison metal duct is typically used for commerical applications. Flexible duct is easier and faster to install so it is typically used for residential purposes.

Saves money long term. Metal duct is a pricey upfront investment yet it saves money by maintaining high indoor air quality and regulating indoor temperature – no matter the outdoor climate.

How we can help…

Trade Air Australia has an in-house team of experts available to discuss your project needs to design, quote and manufacture the right ductwork solution for you.